Public Lighting Networks’

Energy Supply

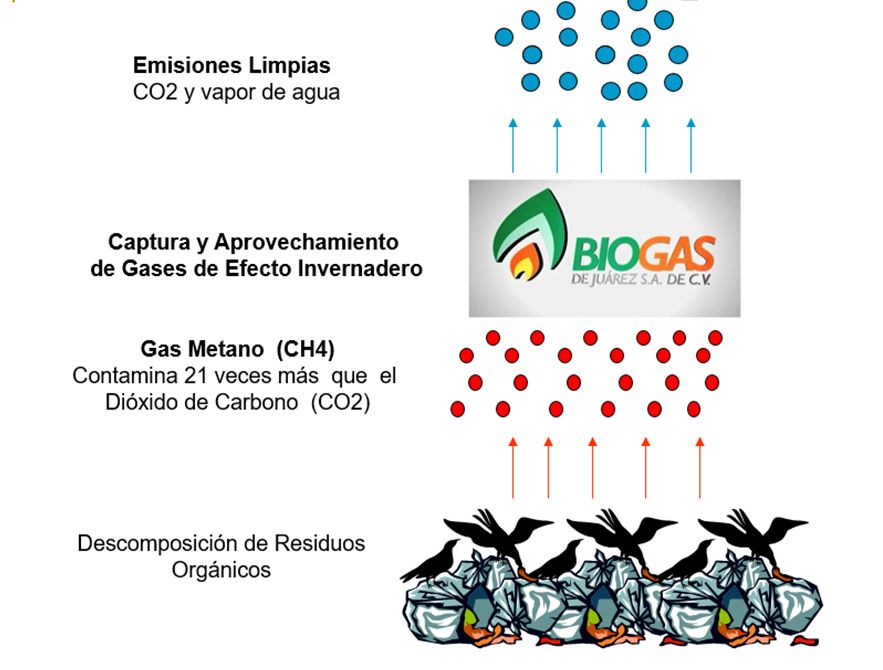

The electricity generated by Biogas complies with the voltage and frequency standards required by the Secretariat of Energy; these standards are evaluated in real time through top notch electronic and computational technology that ensures the quality of the energy that is injected into the national electrical system through the point of interconnection to the federal network.

Once inside the network, the electric power goes to the public lighting circuits of the municipalities of Juárez and Chihuahua.

.